High Performance Water-based Printing Solution

Media Handling Perfected

Stable media feeding and take-up with optional jumbo roll feeder

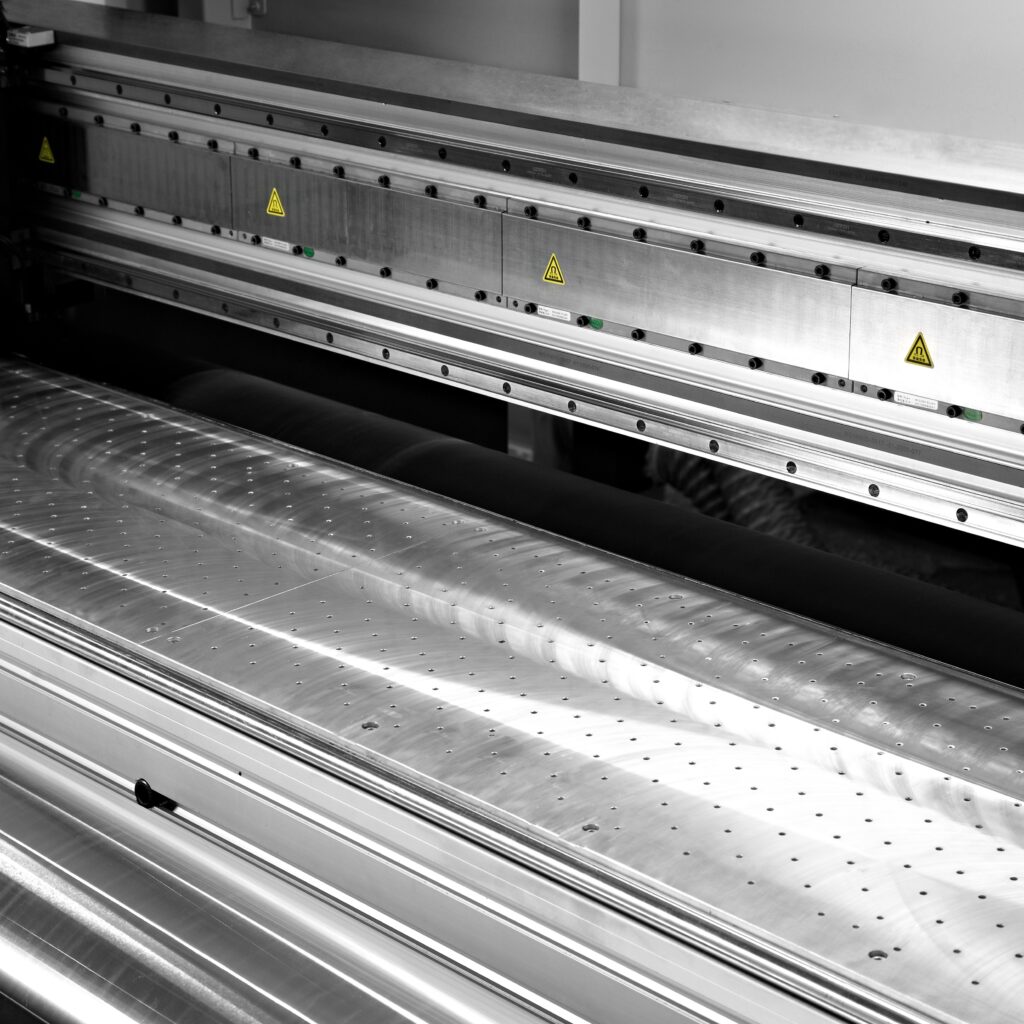

Magnetic Linear Motor

-

Rail beam made of reinforced steal for durability and precision straightness

-

Magnetic levitation motor

-

Improves the stability of print the head carriage’s back and forth movement

-

Carriage speed of 1.2 m/s

-

Enabling maximum productivity

Printing Speeds

Feeding And Winding

-

Tension adjustable feeding system

-

Optimal for transfer paper printing

-

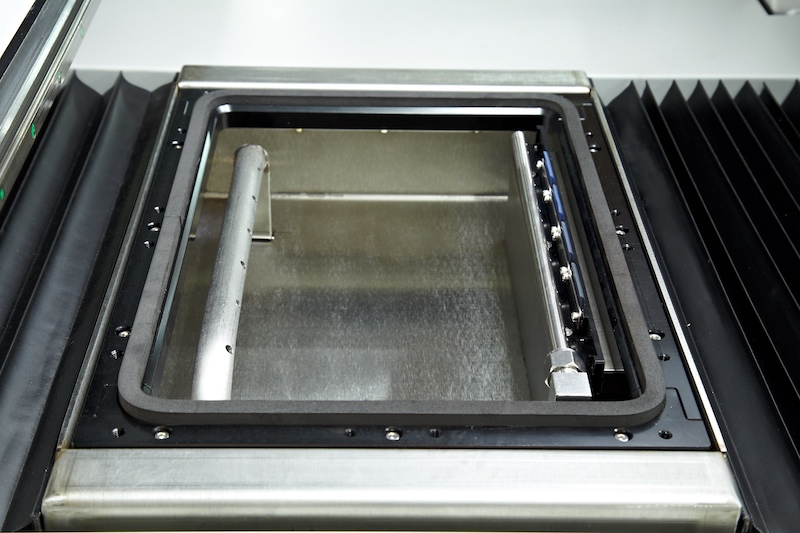

Vacuum print bed which can be adjusted by software to optimize media flatness and improve drop placement accuracy

Efficient Drying

-

Double Infrared IR

-

Optimal for blueback paper printing

-

Vacuum print bed which can be adjusted by software to optimize media flatness and improve drop placement accuracy

Capping Station

-

Four wiper blades for automated cleaning

-

Automated cleaning reduces downtime

-

Special cleaning fluid for high performance and high stability

Protection Included

-

Jam Sensor on both sides of the carriage

-

Detects wrinkled media and prevents head strikes and media jams

-

Ensures increased print head lifetime

Optical Banding Reduction

-

OBR (Optical Banding Reduction) prints passes in gradation-like tone by dispersing ink drops between the passes, which reduces banding, uneven drying of the ink and bidirectional stripe

-

OBR can be set in the software in range

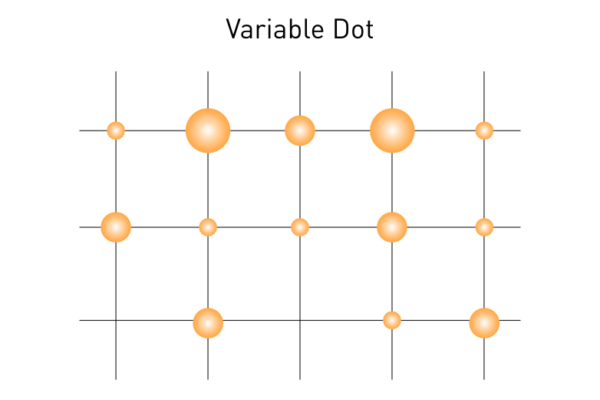

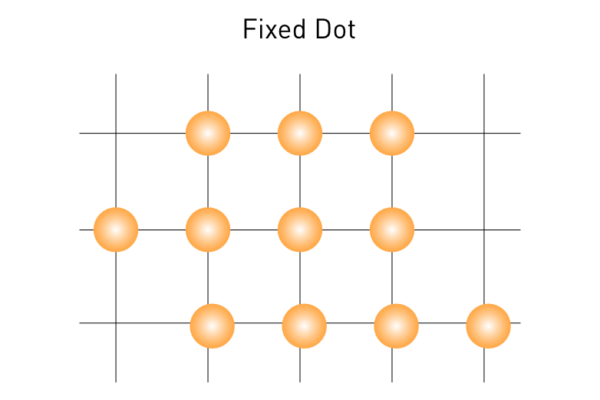

Variable Dot Printing

-

High quality printing due to variable sized droplets

-

Using drop sizes; 5,7 and 12 picolitre in all print modes

Industrial Grade Ink Supply System

Peristaltic Pump Ink Supply

Industrial grade peristaltic pumps for smooth and stable ink flow.

Efficient Degassing Unit

Removes all remaining air from the ink.

Negative Pressure

Automated negative pressure monitoring & adjusting feeding.

Superior Stability

Ensures a stable nozzle firing at high speed printing.

Specifications

Print Heads

Kyocera KJ4B

4 Print Heads

Total 2,656 nozzles

Drop Size 5/7/12 pl

Grayscale

Requirements

Printer and Heater Power 5 kW + 16.5 kW

Power Supply AC 380V/ 220V

Compressed Air 0.6MPA / 0.15m3/hr

Printing

Maximum Printing Width 1900 mm

Carriage Speed 1.2 m/s

RTR (Roll-To-Roll)

Tension-adjustable continuous winding/unwinding control technology

Media

Blueback Paper

Max. Media Width 1950 mm

Media Thickness Maximum 2 mm

Max. roll weight 200 kg

Speeds

Draft Mode 320 m2/h

Production Mode 195 m2/h

Quality Mode 120 m2/h

Ink

Signracer WBP

Available Colours CMYK

Ink Package 5 L bottle

Main Ink Tank Capacity 6 L with level sensor

Dimensions

Length x Width x Height

4200 x 1550 x 1900 mm

Weight 1700 kg