SEE IT IN ACTION

Motorized collecting table with pneumatic ejector for inline cutting.

Automatic XY cutting machine for flexible materials with automatic vertical media alignment correction.

The Hydrospeed Turbo is equipped with 8 industrial Kyocera printheads in symmetrical color alignment. Combined with a magnetic linear motor, providing a carriage speed of 1.2 m/s, the production output is a mind blowing 540 m2/h in draft mode. That is what we call TURBO!

Optional Jumbo Feeding system capable of having Jumbo Rolls with max. diameter of 1 m, weight of 1000 kg, and rolls up to 10,000 meters in length.

Adjustable unit height and angle, fully integrate into production process with optional additional extension in length.

High performing buffer system for in-line cutting with precisely tuned media transport from printer take-up to the XY Cutter. Load balancing technology ensures timely feeding syncronized to match the printer output.

Newest technology infrared heating system specialised on water evaporation. Triple heaters guarantee high temperature required for water resistance even in 1 pass.

Our inks are degassed and use NANO- Size pigment particles, ensuring utmost production stability and increased color vibrancy. Our unique formulation ensures that the ink cures instantly and is suited for outdoor usage.

Workflow Automation

Feeding And Winding

-

Tension adjustable feeding system

-

Optimal for transfer paper printing

-

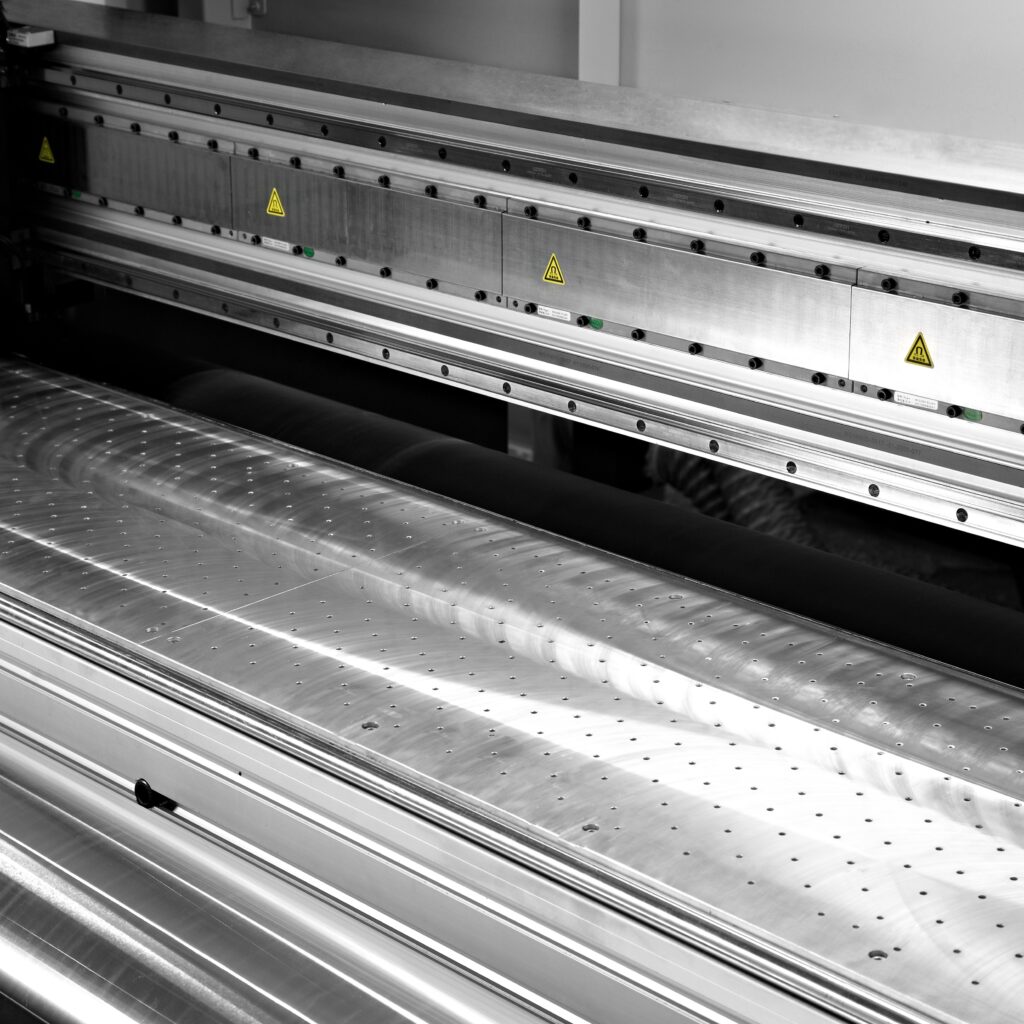

Vacuum print bed which can be adjusted by software to optimize media flatness and improve drop placement accuracy

Efficient Drying

-

Double Infrared IR

-

Optimal for blueback paper printing

-

Vacuum print bed which can be adjusted by software to optimize media flatness and improve drop placement accuracy

Automatic Moisturizing keeps print heads wet during standby

Four Wiper Blades for automatic cleaning

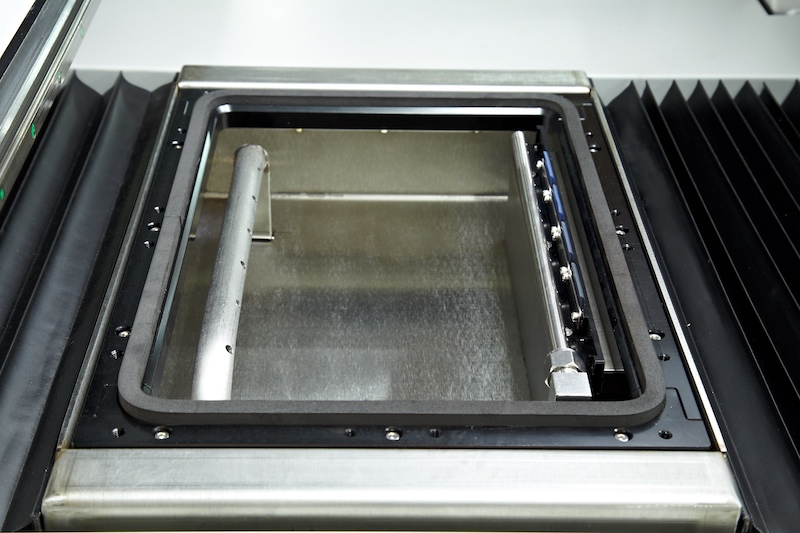

Capping Station

-

Four wiper blades for automated cleaning

-

Automated cleaning reduces downtime

-

Special cleaning fluid for high performance and high stability

Protection Included

-

Jam Sensor on both sides of the carriage

-

Detects wrinkled media and prevents head strikes and media jams

-

Ensures increased print head lifetime

Jam Sensor – Prevents print head strikes and media jams

Optical Banding Reduction

-

OBR (Optical Banding Reduction) prints passes in gradation-like tone by dispersing ink drops between the passes, which reduces banding, uneven drying of the ink and bidirectional stripe

-

OBR can be set in the software in range

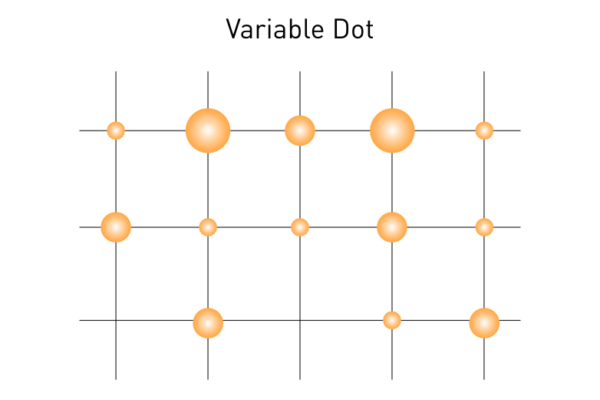

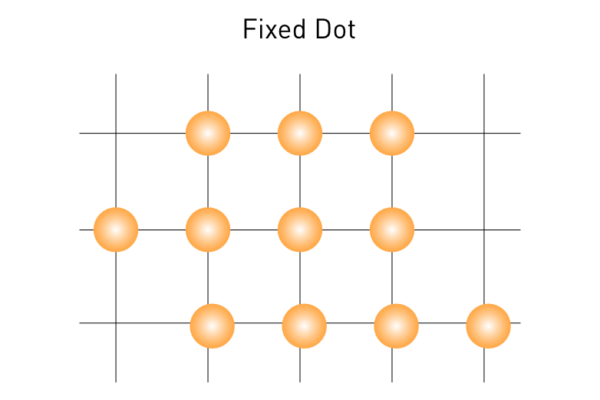

Variable Dot Printing

-

High quality printing due to variable sized droplets

-

Using drop sizes; 5,7 and 12 picolitre in all print modes

Industrial Grade Ink Supply System

Peristaltic Pump Ink Supply

Industrial grade peristaltic pumps for smooth and stable ink flow.

Efficient Degassing Unit

Removes all remaining air from the ink.

Negative Pressure

Automated negative pressure monitoring & adjusting feeding.

Superior Stability

Ensures a stable nozzle firing at high speed printing.